About us

SOCIAL RESPONSIBILITY

INVAZ s.r.o. is a traditional manufacturer of textile materials for health care and industry with more than twenty years of history. In the Czech Republic it is also one of the last manufacturers of dressing materials who decided to maintain production of high-quality cotton bandages.

The company was founded in 2003 and since the very beginning it has profiled itself as a company the aim of which was to provide work for disabled people. Today, it employs more than 50% of disabled people from the total number of employees.

WIDE PRODUCT PORTFOLIO

In terms of production assortment, the company focuses mainly on high quality cotton bandages and dressings in various lengths and widths according to customer’s requirements, various products of gauze and cellulose wadding, and, last but not least, modern sterile compression bandages designed for first aid in rescue services and in the army.

The production portfolio also includes TECASORB – unique textile absorbent dressing with a layer of active carbon for treatment of various wounds (especially inflammatory purulent wounds), which significantly accelerates healing and reduces pain sensation. A variant of a product with active carbon is a sterile carbon adhesive plaster, which is used, among others, when removing dialysis needles where it significantly reduces soreness and healing time.

A secondary product is reinforced paper coated with polyester knitted fabric, which can be used in bookbinding, as a packaging material or for production of envelopes for valuables.

INNOVATION

Since the very beginning of its activity in the medical devices segment the company has been involved in development of new products. It perceives product and process innovation as a driving force of its further development.

Among others, the company participated in development of oxycellulose grid, the feed material for production of haemostatic agents intended to stop bleeding in a wide range of surgical procedures. This product was developed together with Synthesia, a.s., which acquired a stake in the company in 2023 and became its majority owner.

COOPERATION

Also, long-term cooperation with other companies active in the medical device segment, and especially with healthcare professionals whose expertise and experience provide insight into medical care on a wide scale, and are thus very often a source of innovative ideas, helps the company in development of new products.

QUALITY

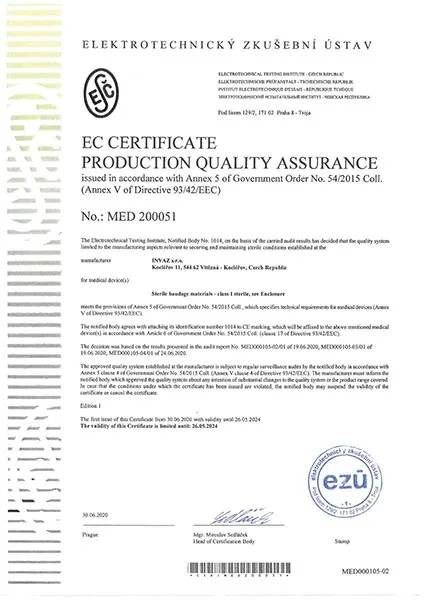

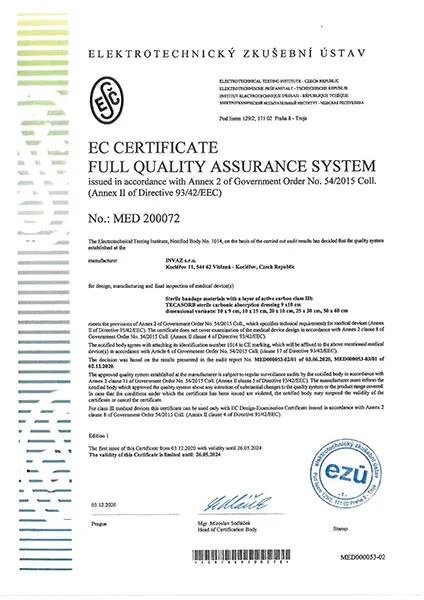

The company‘s products are classified in risk classes I, Is and IIb. Compliance with all relevant EU standards governing production of medical devices is confirmed by the Czech testing company with international competence EZÚ (Electrotechnical Testing Institute, s. p.). The company is also certified according to ČSN EN ISO 9001:2016 and ČSN EN ISO 13485 ed. 2:2016.

Quality policy:

General requirements:

Company has established, documented and maintained a quality management system, which serves as a means to assess the ability to meet the relevant applicable regulatory requirements as well as to meet customer requirements.

The aim is the improvement and maintenance of the effectiveness of the quality management system to ensure compliance with the requirements stated in the EN ISO 9001 and in the EN ISO 13485 standard for the production of medical devices through the efficient application of this system.

Furthermore, the objective is to ensure compliance with the requirements of Council Directive 93/42/EEC and the Regulation of the European Parliament and of the Council EU 2017/745 according to Article 120 for the transitional period with the gradual implementation of other requirements, aiming to ensure conformity with this regulation.

Furthermore, the aim is to continue to develop and improve relations with the owner of leased production facilities.

To achieve this aim, we have a team of qualified and competent employees, where each manager is responsible for improving quality in their department. They take into account the aims of improving quality not only in their department, but throughout the company. Therefore, each employee contributes to the realization of the company’s strategic aims.

Quality Policy:

The top management is committed to producing safe and fully functional medical devices in accordance with applicable legal / regulatory requirements, to ensure the satisfaction of the customer and end-user – the patient.

Furthermore, the top management is committed to maintaining the effectiveness of the quality management system using a process approach to setting objectives for each area of the quality management system, which we review annually.